Aluma Hyde II and Magpul Flat Dark Earth

I've been wanting to paint one of my rifles, but despite a lot of research into the different paint options, I couldn't quite bring myself to paint a rifle without some experimentation. I decided to take a couple of the ASC 15-round magazines that I got and try painting them to match the Magpul Flat Dark Earth (FDE) furniture that I had on the gun. I decided to use Brownell's Aluma Hyde II over Duracoat or a similar paint, as I did not have access to a HVLP sprayer or a compressor. These are the same magazines that I made plugs for hunting capacity, you can read that post here.

|

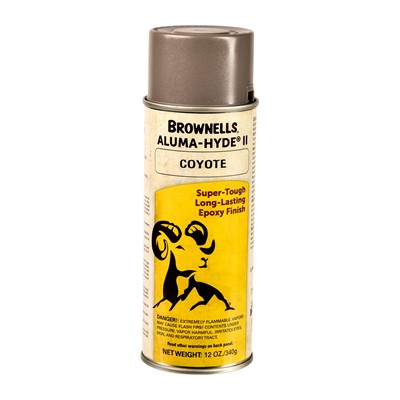

| Here is a picture link to Brownell's Coyote Aluma-Hyde II. |

After a little research, I landed on the Aluma Hyde Coyote color as the most likely match for FDE. I ordered a can of the paint, along with a forearm. I decided that I wanted to use an actual firearms coating for a (hopefully) more durable finish than the popular Krylon paint jobs that I see so often on the web. Krylon has the advantage of being easy to strip and replace if you want to switch it around, but for a more permanent finish, it isn't as durable as an actual firearms coating.

|

| Factory ASC 6.8 SPC, 15 round magazine. |

The first photo above is the factory finish that came on the ASC magazine. It is a fairly common military type dry film finish. The magazine above has been placed in the gun a couple times and carried in the field once on a morning coyote hunt, but has not been fired. The finish is already scuffed up, even from fairly light handling.

|

| Left: Sanded magazine, right: original factory finish. |

Once the metal has been prepped, it needs to be thoroughly degreased. I used brake cleaner from Walmart, but Brownells highly suggest using their own brand of TCE cleaner. I guess I will see in the long run if the brake cleaner holds up.

For the spraying of the metal, I used the method that Brownells suggested on their site. I first sprayed one really light coat, not trying to cover all the metal. I then used a blow dryer to warm the metal and blow some hot air until the Aluma Hyde looked dry. I followed this with a second coat, just like the first. Then another blow drying. The third coat I sprayed on a little thicker. I was careful to not spray it on thick enough to cause runs, but I used the third coat to try to cover all the metal. After another quick blow dry, I put the fourth and final coat. The fourth coat was just used to touch up any places that didn't look like they had been completely coated with the first two coats. This was followed by one last blow drying.

|

| ASC magazines with Aluma Hyde drying in the oven. |

|

| Finished 6.8 SPC ASC magazine with Aluma Hyde II |

After about a week I took one of the magazines and inserted it repeatedly into the mag well of the rifle. I did notice that the mag catch almost immediately scraped off a section of the Aluma Hyde where it first contacted the catch. I was a little disappointed at first, but a quick check of my other magazines with teflon coatings showed that every single one of them had bare metal for the entire length the mag catch travels. I decided to leave the other magazine out of the mag well for a couple more weeks to see if the Aluma Hyde sets any better then, but I'm guessing that the mag catch will wear through pretty much any surface over time.

|

| ASC 6.8 SPC magazine with Aluma Hyde II Coyote, Magpul FDE MIAD grip and XTM rail panel. |

Let me know what colors you have used and what products (duracoat, cerakote, etc.) in the comments below. This was my first foray into firearm finishes, but I don't think it will be the last.

Nice!! I want to paint my Magpul mags in FDE not sure the Aluma Hyde II will work on spiffed up plastic (polymer) but I will research.

ReplyDeleteNICE job!

MiamiNice57

Nice!! I want to paint my Magpul mags in FDE not sure the Aluma Hyde II will work on spiffed up plastic (polymer) but I will research.

ReplyDeleteNICE job!

MiamiNice57

Sorry for the long delay in responding. According to the Brownell's website you should be able to use Aluma-Hyde II on plastics. Their description says that it is: "a durable finish that sticks to all properly prepared aluminum and alloy surfaces, steel and plastics."

ReplyDeleteGood luck with your project!

so you finally go with hyde coyote instead of hyde magpul fde ? have you tried to compared hyde coyote with hyde magpul fde ? which one will get close to default magpul fde ?

ReplyDelete